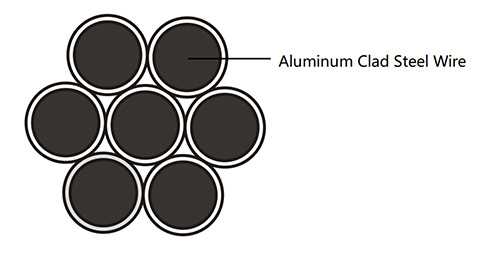

Aluminium Clad Steel (ACS) wire consists of a central steel core with a layer of highconductivity aluminium extruded over it. The aluminium layer forms a seamless metallurgical tie with the steel wire to guarantee permanent bonding during rewinding and stranding.And it is widely used in the overhead power distribution system of our country and designed for aerial power transmission lines, river crossings etc.

1.APPLIACATION: DISTRIBUTION LINE POWER NETWORKS.

2.STANDARD: ASTM B415,ASTM B416,DIN 48201,GB/T 1179-2008.

3.INSTALLATION CONDITIONS: OPEN AIR.

4.CONDUCTIVITY: USUALLY 20.3%IACS, 40%IACS.

5.PACKAGING: BY ROLL, BY POLYWOOD OR WOODEN OR STEEL-WOODEN REEL/DRUM.

Aluminium Clad Steel (“ACS”) wire consists of a central steel core with a layer of high conductivity aluminium extruded over it.

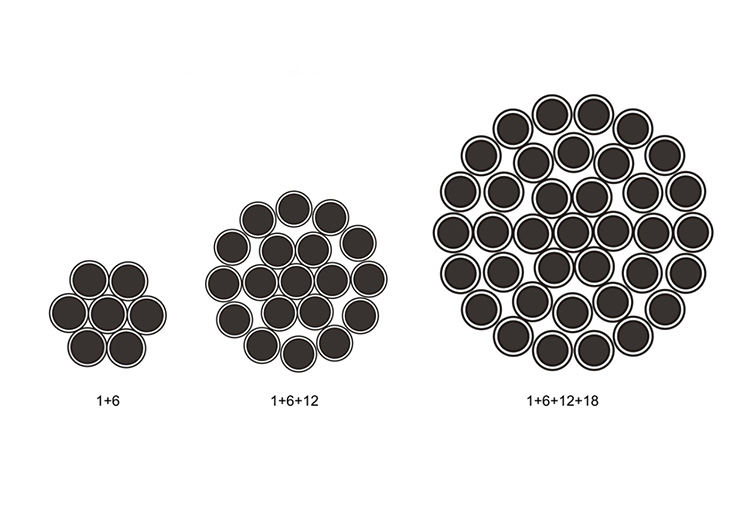

Generally, the ACS Conductor is formed by the following construction:

| ALUMINIUM CLAD STEEL STRAND ASTM B415 | |||||||

| Nominal Diameter | Area | Min.Tensile Strength | Rated Strength | Min.Coating Thickness | Max. D.C. Resistance at 20℃ | Weight | |

| mm | AWG | mm2 | mpa | kN | mm | Ω/km | kg/km |

| 2.052 | 12 | 3.307 | 1340 | 4.5 | 0.103 | 25.64 | 21.8 |

| 2.304 | 11 | 4.169 | 1340 | 5.6 | 0.115 | 20.34 | 27.49 |

| 2.5896 | 10 | 5.26 | 1340 | 7.1 | 0.13 | 16.12 | 34.66 |

| 2.904 | 9 | 6.633 | 1340 | 8.9 | 0.145 | 12.78 | 43.65 |

| 3.264 | 8 | 8.367 | 1340 | 11.2 | 0.163 | 10.14 | 55.14 |

| 3.477 | 7 | 9.495 | 1310 | 12.4 | 0.174 | 8.93 | 62.57 |

| 3.665 | 7 | 10.55 | 1280 | 13.5 | 0.183 | 9.04 | 69.48 |

| 3.934 | 6 | 12.16 | 1240 | 15.1 | 0.197 | 6.93 | 80.13 |

| 4.115 | 6 | 13.3 | 1210 | 16.0 | 0.206 | 6.38 | 87.62 |

| 4.392 | 5 | 15.15 | 1170 | 17.7 | 0.220 | 5.60 | 99.84 |

| 4.620 | 5 | 16.76 | 1140 | 19.1 | 0.231 | 5.06 | 110.50 |

| 4.775 | 4 | 17.91 | 1100 | 19.7 | 0.239 | 4.73 | 118 |

| 5.189 | 4 | 21.15 | 1070 | 22.6 | 0.259 | 4.01 | 139.34 |

| ALUMINIUM CLAD STEEL STRAND ASTM B416 | |||||||

| Code Number | Calculated Area | No. Of Wires | Diameter | Weight | Rated Strength | Max. D.C. Resistance at 20℃ | |

| Wire | Cond. | ||||||

| mm2 | mm | mm | kg/km | kN | Ω/km | ||

| 3 No 5AWG | 50.32 | 3 | 4.62 | 9.96 | 334.1 | 54.42 | 1.6990 |

| 3 No 6AWG | 39.00 | 3 | 4.11 | 8.87 | 265.0 | 45.74 | 2.1420 |

| 3 No 7AWG | 31.65 | 3 | 3.67 | 7.90 | 210.1 | 38.36 | 2.7010 |

| 3 No 8AWG | 25.10 | 3 | 3.26 | 7.03 | 166.7 | 32.06 | 3.4060 |

| 3 No 9AWG | 19.90 | 3 | 2.91 | 6.26 | 132.2 | 25.43 | 4.2940 |

| 3 No 10AWG | 15.78 | 3 | 2.59 | 5.58 | 104.8 | 20.16 | 5.4150 |

| 7 No 5AWG | 117.40 | 7 | 4.62 | 13.90 | 781.1 | 120.27 | 0.7426 |

| 7 No 6AWG | 93.10 | 7 | 4.11 | 12.40 | 619.5 | 101.14 | 0.9198 |

| 7 No 7AWG | 73.87 | 7 | 3.67 | 11.00 | 491.1 | 84.81 | 1.1600 |

| 7 No 8AWG | 58.56 | 7 | 3.26 | 9.78 | 389.6 | 70.88 | 1.1463 |

| 7 No 9AWG | 46.44 | 7 | 2.91 | 8.71 | 308.9 | 56.20 | 1.8440 |

| 7 No 10AWG | 36.83 | 7 | 2.59 | 7.76 | 245.1 | 44.58 | 2.3250 |

| 7 No 11AWG | 29.21 | 7 | 2.30 | 6.91 | 194.4 | 35.35 | 2.9320 |

| 7 No 12AWG | 23.16 | 7 | 2.05 | 6.16 | 154.2 | 28.03 | 3.6970 |

| 19 No 5AWG | 318.70 | 19 | 4.62 | 23.10 | 2129.0 | 326.39 | 0.2698 |

| 19 No 6AWG | 252.70 | 19 | 4.11 | 20.60 | 1688.0 | 274.55 | 0.3402 |

| 19 No 7AWG | 200.40 | 19 | 3.67 | 18.30 | 1339.0 | 230.18 | 0.4290 |

| 19 No 8AWG | 158.90 | 19 | 3.26 | 16.30 | 1062.0 | 192.41 | 0.5409 |

| 19 No 9AWG | 126.10 | 19 | 2.91 | 14.50 | 842.0 | 152.58 | 0.6821 |

| 19 No 10AWG | 99.96 | 19 | 2.59 | 12.90 | 667.7 | 121.00 | 0.8601 |

| 37 No 5AWG | 620.60 | 37 | 4.62 | 32.30 | 4170.0 | 635.43 | 0.1394 |

| 37 No 6AWG | 492.20 | 37 | 4.11 | 28.80 | 3307.0 | 534.85 | 0.1757 |

| 37 No 7AWG | 390.30 | 37 | 3.67 | 25.70 | 2623.0 | 448.09 | 0.2216 |

| 37 No 8AWG | 309.50 | 37 | 3.26 | 22.90 | 2080.0 | 374.67 | 0.2794 |

| 37 No 9AWG | 245.50 | 37 | 2.91 | 20.30 | 1649.0 | 279.11 | 0.3523 |

| 37 No 10AWG | 194.70 | 37 | 2.59 | 17.90 | 1308.0 | 235.61 | 0.4443 |

| ALUMINIUM CLAD STEEL STRAND DIN 48201 | |||||||

| Code Number | Calculated Area | No. Of Wires | Diameter | Weight | Rated Strength | Max. D.C. Resistance at 20℃ | |

| Wire | Cond. | ||||||

| mm2 | mm2 | mm | mm | kg/km | Kn | ohm/km | |

| 25 | 24.52 | 7 | 2.10 | 6.3 | 162 | 31.56 | 3.5460 |

| 35 | 34.36 | 7 | 2.50 | 7.5 | 229 | 44.72 | 2.4990 |

| 50 | 49.48 | 7 | 3.00 | 9.0 | 330 | 64.40 | 1.7360 |

| 70 | 65.81 | 19 | 2.10 | 10.5 | 441 | 85.65 | 1.3130 |

| 95 | 93.27 | 19 | 2.50 | 12.5 | 626 | 121.39 | 0.9250 |

| 120 | 116.99 | 19 | 2.80 | 14.0 | 785 | 152.26 | 0.7370 |

| 150 | 147.11 | 37 | 2.25 | 15.7 | 990 | 191.46 | 0.5870 |

| 185 | 181.62 | 37 | 2.50 | 17.5 | 1221 | 236.38 | 0.4760 |

| 240 | 242.54 | 61 | 2.25 | 20.2 | 1635 | 299.05 | 0.3570 |

| 300 | 299.43 | 61 | 2.50 | 22.5 | 2017 | 369.20 | 0.2890 |

| ALUMINIUM CLAD STEEL STRAND GB/T 1179-2008(JLB1A,JLB1B) | ||||||||||

| Nominal Area St | Code Number | Area | Number of Wires | Diameter | Linear Mass | Rated Strength | Max. D.C. Resistance at 20℃ |

|||

| Wire | Cond. | JLB1A | JLB1B | JLB1A | JLB1B | |||||

| mm2 | mm2 | mm | mm | kg/km | kg/km | kN | kN | Ω/km | ||

| 15 | 4 | 12 | 7 | 1.48 | 4.43 | 80.1 | 79.4 | 16.08 | 15.84 | 7.1592 |

| 20 | 6.3 | 18.9 | 7 | 1.85 | 5.56 | 126.2 | 125.0 | 25.33 | 24.95 | 4.5455 |

| 30 | 10 | 30 | 7 | 2.34 | 7.01 | 200.3 | 198.5 | 40.20 | 39.60 | 2.8637 |

| 35 | 12.5 | 37.5 | 7 | 2.61 | 7.84 | 250.4 | 248.1 | 50.25 | 49.50 | 2.2910 |

| 50 | 16 | 48 | 7 | 2.95 | 8.86 | 320.5 | 317.5 | 64.31 | 63.36 | 1.7898 |

| 75 | 25 | 75 | 7 | 3.69 | 11.08 | 500.7 | 496.2 | 93.75 | 99.00 | 1.1455 |

| 120 | 40 | 120 | 7 | 4.67 | 14.02 | 801.2 | 793.9 | 132.00 | 158.40 | 0.7159 |

| 120 | 40 | 120 | 19 | 2.84 | 14.18 | 805.0 | 797.7 | 160.80 | 158.40 | 0.7194 |

| 200 | 63 | 189 | 19 | 3.56 | 17.79 | 1267.9 | 1256.4 | 240.03 | 249.48 | 0.4568 |

| 300 | 100 | 300 | 19 | 3.21 | 22.49 | 2017.3 | 1999.0 | 402.00 | 396.00 | 0.2884 |

| 350 | 125 | 375 | 19 | 3.59 | 25.15 | 2521.7 | 2498.3 | 476.25 | 495.00 | 0.2307 |

| 450 | 150 | 480 | 19 | 4.06 | 28.45 | 3227.7 | 3198.3 | 580.80 | 633.60 | 0.1803 |

| 600 | 200 | 600 | 19 | 4.54 | 31.81 | 4034.7 | 3997.9 | 684.00 | 792.00 | 0.1442 |

| 600 | 200 | 600 | 19 | 3.54 | 31.85 | 4040.6 | 4003.8 | 762.00 | 792.00 | 0.1444 |

| ALUMINIUM CLAD STEEL STRAND GB/T 1179-2008(JLB2) | ||||||||

| Nominal Area St | Code Number | Area | Number of Wires | Diameter | Linear Mass | Rated Strength | Max. D.C. Resistance at 20℃ |

|

| Wire | Cond. | |||||||

| mm2 | mm2 | mm | mm | kg/km | kN | Ω/km | ||

| 35 | 16 | 36.2 | 7 | 2.56 | 7.69 | 216.4 | 39.04 | 1.7896 |

| 55 | 25 | 56.5 | 7 | 3.21 | 9.62 | 338.2 | 61.00 | 1.1454 |

| 100 | 40 | 90.4 | 7 | 4.05 | 12.2 | 541.1 | 97.61 | 0.7159 |

| 100 | 40 | 90.4 | 19 | 2.46 | 12.3 | 543.7 | 97.61 | 0.7193 |

| 150 | 63 | 142 | 19 | 3.09 | 15.4 | 856.4 | 153.73 | 0.4567 |

| 220 | 100 | 226 | 37 | 2.79 | 19.5 | 1362.6 | 244.02 | 0.2884 |

| 300 | 125 | 282 | 37 | 3.12 | 21.8 | 1703.2 | 305.02 | 0.2307 |

| 350 | 160 | 362 | 37 | 3.53 | 24.7 | 2180.1 | 390.43 | 0.1803 |

| 450 | 200 | 452 | 37 | 3.94 | 27.6 | 2725.1 | 488.03 | 0.1442 |

| 450 | 200 | 452 | 61 | 3.07 | 27.6 | 2729.1 | 488.03 | 0.1444 |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.